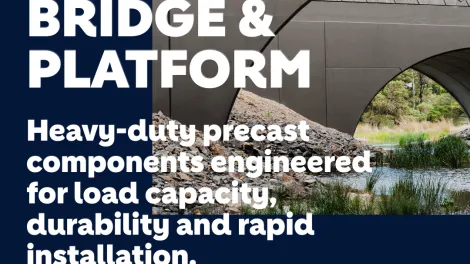

Tulladunna Bridge Replacement

Precast Uniculvert® Modules Enable Rapid Rail Bridge Replacement

Background

Replacing Ageing Timber Bridge Infrastructure to Improve Freight Reliability

The Tulladunna Bridge crosses the Namoi River in rural New South Wales and forms part of a key regional freight rail corridor. As part of the Bridges for the Bush Initiative, the Australian Rail Track Corporation (ARTC) undertook the replacement of the existing timber bridge to improve safety, reliability and freight productivity while reducing long-term maintenance requirements.

Given the importance of the rail line, minimising disruption during construction was a critical project driver.

The Challenge

Delivering a Long-Span Rail Bridge Within a Tight Construction Window

The project required a cost-effective bridge solution capable of meeting heavy rail loading requirements while being installed within a highly constrained possession period. Late-stage design changes also needed to be accommodated without impacting the construction schedule.

Durability and compliance with Australian Standards were essential, with all precast elements required to achieve a 100-year design life.

The Solution

Supplying a Modular Precast Bridge System Optimised for Speed and Efficiency

ARTC engaged Humes to supply a precast modular bridge solution using Uniculvert® modules. Humes manufactured and supplied:

- 166 Uniculvert® modules

- 166 bolt-on precast kerbs

- Four freestanding wing walls

- 12 prestressed concrete girders

Working closely with the project designer, Humes modified one Uniculvert® module to suit existing mould stocks, improving project economy. Reinforcement designs were also optimised to enhance fabrication efficiency, with all amendments approved prior to manufacture.

The system was designed to AS 5100:2004 for 280LA loading, with all precast components manufactured in accordance with AS 1597.2.

Outcome

394 m Rail Bridge Installed in Just Six Days

Using the Uniculvert® modular system, the complete 394 m rail bridge was installed in just six days — a 40% reduction against the original two-week installation program. The rapid installation minimised disruption to rail operations while delivering significant cost and program efficiencies.

The use of high-quality precast components, combined with efficient product design, enabled late design changes to be incorporated without compromising the construction schedule, resulting in a durable, long-term bridge solution for regional NSW rail infrastructure.